Views: 75 Author: Site Editor Publish Time: 2021-11-26 Origin: Site

CNC machining is the manufacture and processing of parts and products under computer control.

Numerical control processing involves the use of computer numerical control (CNC) machine tools to reshape and resize a piece of material (ie, a workpiece) by automatically removing material. Normally, the material used is plastic or metal, and when the removal is complete, the finished product or product has been produced.

This process is also called subtractive manufacturing. In order to perform CNC machining, computer applications are used to control the movement of the machine tool.

The CNC machining process includes the most common milling and turning, followed by grinding, EDM and so on.

Milling

Milling is the use of a rotating tool on the surface of the workpiece, moving along 3, 4, or 5 axes. Milling is basically the cutting or trimming of the workpiece, which can quickly process complex geometric shapes and precision parts from metal or thermoplastics.

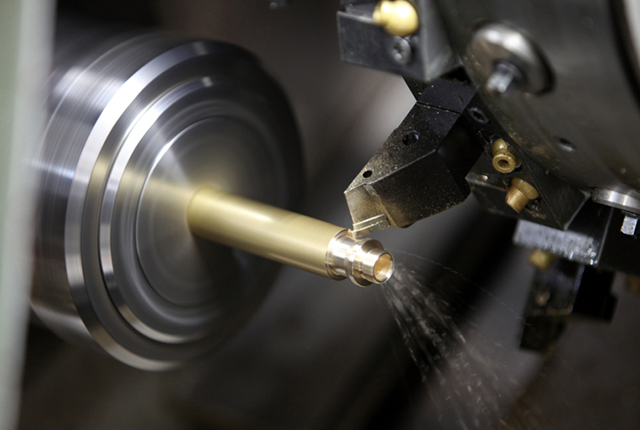

Turning

Turning is the use of a lathe to manufacture parts that contain cylindrical features. The workpiece rotates on the shaft and contacts the precision turning tool to form circular edges, radial and axial holes, grooves and grooves.

Compared with traditional manual machining, CNC machining is much faster. As long as the computer code is correct and conforms to the design, the finished product has a high dimensional accuracy and small errors.

CNC manufacturing is an ideal rapid prototyping manufacturing method. It can also be used to manufacture end-use products and components, but it is usually only cost-effective in short-term production runs in low volumes.

CNC milling involves removing material using rotating tools. Either the workpiece remains stationary and the tool moves onto the workpiece, or the workpiece enters the machine tool at a predetermined angle. The more moving axes of a machine, the more complex the forming process and the faster the speed

3 Axis

3 axis machining implies that the workpiece remains in the same position while the cutting tool operates along the XYZ plane to trim away material. This is suitable for parts that don’t require a lot of depth and detailing. 3 axis machining is most commonly used to produce mechanical components and is best suited for:

Automatic/interactive operation

Milling slots

Drilling holes

Cutting sharp edges

4 Axis

4 axis machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut around the B axis. This method is beneficial when holes or cuts need to be made on the sides of a workpiece. The addition of a fourth axis (A axis) allows a workpiece to be automatically flipped over, so the machine can remove material from both sides. 4 axis machining is multifunctional and can be used for:

Intermittent cutting

Continuous cutting

Engraving curved surfaces

5 Axis

5 Axis machining implies that a workpiece can be automatically manipulated from five sides at one time. In addition to automatic movements along the X, Y, and Z axes, 5 axis CNC machines can select two of the three rotational axes (A,B,C) to use. The A, B, and C axes perform a 180° rotation around the X, Y, and Z axes, correspondingly. This type of machining is used in the automobile, aerospace, and boating industries. Application is commonly favored for extremely complex components that are solid and would otherwise have to be cast. 5 axis machining requires greater CNC programming preparation time to accommodate complex rotatory movement, but allows one workpiece to be worked on all five sides during one operation. 5 axis machining is beneficial when components require a great deal of intricacy and quick precision. This includes:

Feature accuracy

Increased productivity

Higher quality finishes

Cutting intricate details

Machining complex shapes