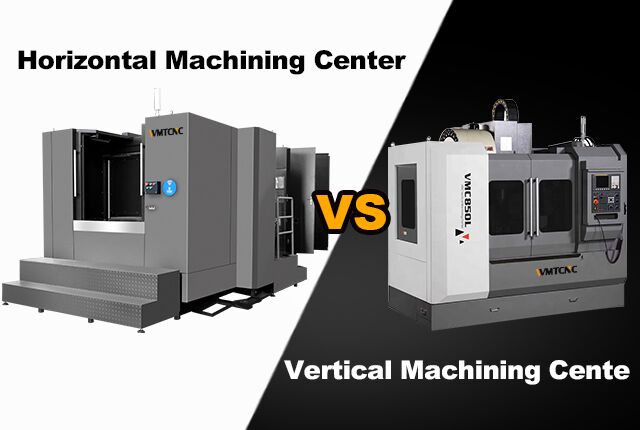

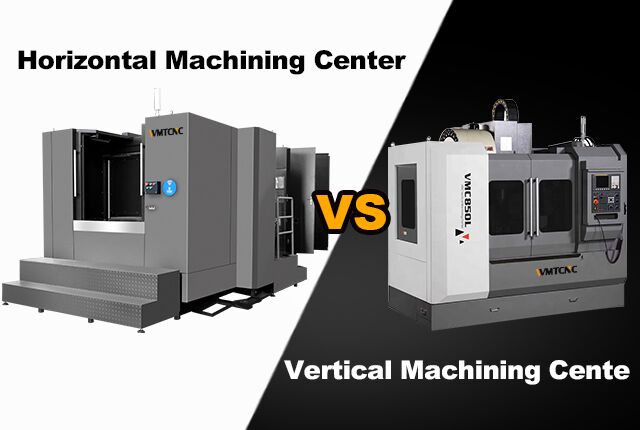

2022-09-04 Today, let's talk about how to distinguish between the horizontal machining center and vertical machining center.

Read More

2021-12-12 WMT CNC has some experienced engineers, they often give us some good application advice, in order to salesman can better communicate with customers. Now, we will introduce 7 tips to better CNC turning.Increase the speedThis really applies most when using carbide tools. When you increase the surface

Read More

2021-12-02 Today we will discuss the difference between servo motor and stepper motor. 1.CostThe cost for a servo motor and servo motor system is higher than that of a stepper motor system with equal power rating.This feature would have to go to stepper motors.Steppers are generally cheaper than servo motors t

Read More

2021-11-20 A lathe is a very useful machine. By turning the workpiece, one is able to make symmetrical or balanced parts. Everything from simple wood bowls to complex engine crankshafts can be turned on a lathe. Lathes are a major tool in the machinist trade, as well as woodwork and automotive applications.Lat

Read More

2021-11-11 How to choose the CNC machining center correctly?1. Confirm the processing target. Choose the typical processing target among the many parts produced by the enterprise, namely the part family selection. The processing center is suitable for the production of multiple varieties and small batches.2. T

Read More

2021-11-03 The definition of a three-axis CNC machine tool enables the machine tool to move three different axes at the same time. CNC milling is one of the most commonly used and most important CNC machining methods in machining. In addition to milling the surface of various parts, it can also mill complex su

Read More

2021-10-29 A brake lathe cures noise and vibration problems that we often experience after heavy brake usage. After all, there's nothing quite like the feel of brake pads on freshly resurfaced rotors.Maintenance and ServiceCleaningKeep the lathe as clean as possible for trouble-free operation, as well as safet

Read More

2021-09-29 Many people who work in the manufacturing industry, even those who have worked in it for years, have a difficult time knowing the difference between a CNC Turning Center and a CNC Lathe Machine. After all, both parts are made for use as tooling components, bushings, adapters, and threaded inserts. A

Read More

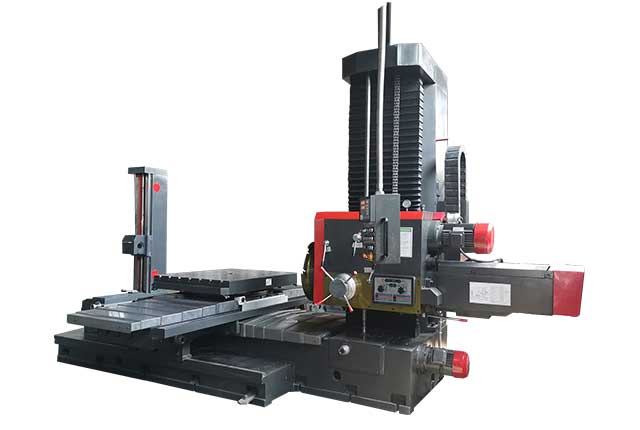

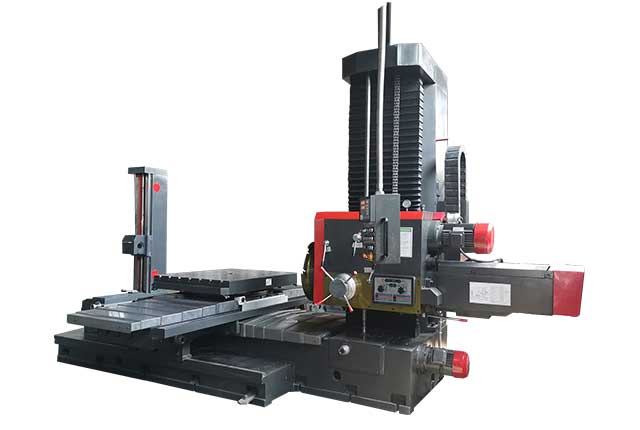

2021-09-25 What is a WHAT IS A HORIZONTAL BORING MILL?A horizontal boring mill is a machine tool that drills holes in a horizontal direction, and there are three types including floor, table, and planer. Boring mills allow for extremely large parts to be easily machined and allows end-users to reach small cavi

Read More

2021-09-16 Radial Drilling MachineDrilling Machine is to make circular holes on the components with the help of Drill bits. But, the purpose of the Radial Drilling Machine is used to drill the holes in the given radial distance and this will be used, when the component size is large in terms of height.When the

Read More