Call Us Now

Tel :

0086-566-2091958Whatsapp/Wechat :

0086-18656680921

VMC1050L

WMTCNC

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Main Features:

1. 4 Axis, 5 axis is available, 5 axis cnc machining centre VMC1050 vertical milling machine.

| Specification | VMC1050L |

| Worktable | |

| Worktable size (L×W) | 1000×500mm |

| T-slots size (N×W×D) | 5-18x90mm |

| Travel | |

| X/Y/Z axis travel | 1000/500/500mm |

| Machining range | |

| Distance from spindle center to column | 550mm |

| Distance from spindle nose to worktable surface | 120-620mm |

| Spindle | |

| Spindle taper | BT40 |

| Spindle power | 7.5kw |

| Max. spindle speed | 8000rpm |

| Feed | |

| Max. feed speed | 10m/min |

| Rapid feed speed (X/Y/Z) | 24/24/20m/min |

| Ball screw (diameter+lead) | |

| X/Y/Z axis ball screw | 4012 |

| Tool magazine | |

| Tool magazine capacity | 16T/24T(optional) |

| Max. length of tool | 300mm |

| Tool change time | 7s/1.5s |

| Positioning accuracy (National standard) | |

| Positioning accuracy (X/Y/Z) | ±0.005mm |

| Re-positioning accuracy(X/Y/Z) | ±0.003mm |

| Machine dimension | |

| L×W×H | 2850×2300×2300mm |

| Machine weight | |

| Max. loading of worktable | 500kg |

| Machine weight | 5400kg |

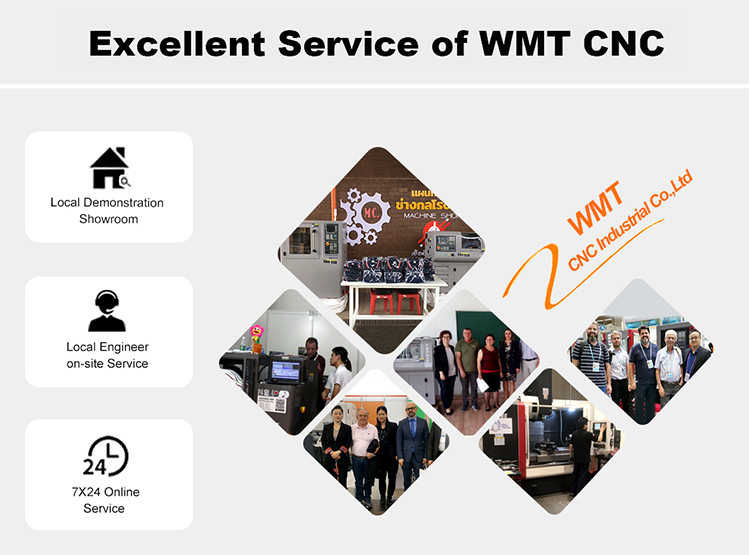

Company Profile