Call Us Now

Tel :

0086-566-2091958Whatsapp/Wechat :

0086-18656680921

QK1330

WMT

| Availability: | |

|---|---|

| Quantity: | |

Product Description

High rigidity casting bed

High precision spindle bearing

Bed guideways industively hardened

| Specification | QK1330 | |

| Max dia.swing over bed(mm) | 800 | |

| Max dia.swing over cross slide(mm) | 480 | |

| Max.length of work-piece(mm) | 1500 3000 4000 5000 | |

| Width of bed(mm) | 600/755 | |

| Spindle bore(mm) | 305 | |

| Power of spindle motor(kw) | 15 | |

| Mode of spindle speed | Two gears, smooth adjustment | |

| Range of spindle speed(r/min) | (L):20-100 | |

| (H):100-300 | ||

| Max.traverse of X/Z(mm) | X:450/550 | |

| Z:1250 | ||

| X/Z rapid traverse(r/min) | 4000 | |

| X-axis motor | Speed(r/min) | 1500 |

| Torgue(N.m) | 15/18 | |

| Power(kw) | 2.8 | |

| Z-axis motor | Speed(r/min) | 1500 |

| Torgue(N.m) | 18/22 | |

| Power(kw) | 3.8 | |

| Tailstock quill | Diameter(mm) | 100 |

| Travel(mm) | 250 | |

| Taper | Morse NO.6 | |

| Electric tool-post | Model | LDB4-6180 |

| No.of tool stations | Vertical four-station | |

| Dimension(mm) | 280×280 | |

| Turret indexing time(s) | 2.6 | |

| Chuck | K11-630 three jaw chuck | |

| Positioning accuracy(mm) | 0.02 | |

| Repositioning accuracy(mm) | 0.01 | |

| Overall dimensions(L*W*H)(mm) | 4600×2060/2100×2100 | |

| Machine weight(kgs) | 7500/9500 | |

Standard Accessories:

1. Cooling system

2. Auto-lubricating system

3. Work lamp

4. GSK-980TDc controller with feeding servo motor

5. 4-Position electrical tool post

6. Unitary iron casting machine stand

7. Manual 3-jaw chuck 2 pcs

Optional Accessories:

1. GSK218M controller

2. Siemens 808D controller

3. Siemens 808D Advance controller

4. Fanuc Oi TF controller

5. 6/8-Position electrical tool post

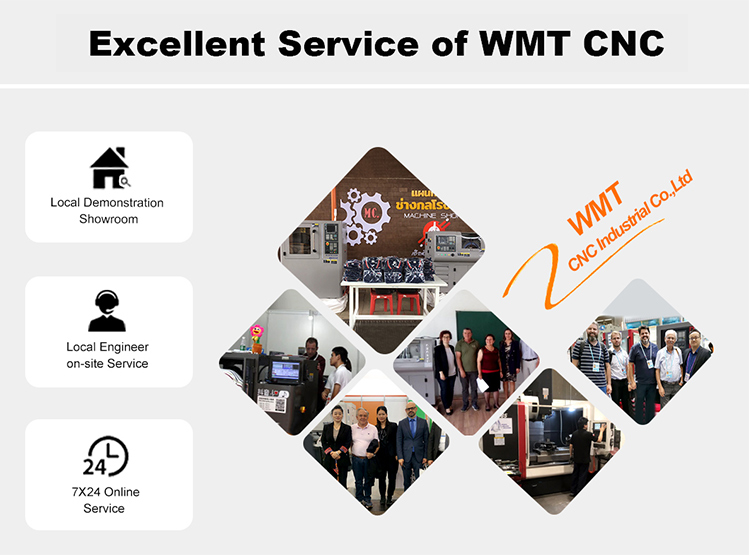

Company Information